$410.83 USD

UTP 690 Electrode

Description

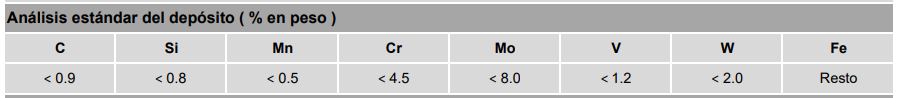

UTP 690 features excellent welding properties and a smooth, even finish due to its spray arc transfer. Slag removal is easily accomplished. The weld deposit is equivalent to high-speed steel with increased molybdenum content.

Application

Field UTP 690 is used for the repair and production of cutting tools, particularly for the reconstruction of cutting edges and working surfaces. The deposit is highly resistant to friction, compression, and impact, as well as high temperatures up to 550°C. Producing new tools by welding onto unalloyed or low-alloy base metals is also possible through cladding on cutting edges.

Welding Instructions

Clean the area to be welded. Preheat according to the base metal application. Maintain the electrode in a vertical position with a short arc. Electrodes that have been exposed to the environment for a long time should be rebaked at 300°C for two hours.

Preheating High-Speed Steels

Clean the area to be welded. For high-speed steels, preheat to 400 - 600°C. Maintain this temperature throughout the entire welding process, followed by slow cooling.